Electric Fuel Pump

Automotive Electronic Fuel Pump

how do I do it right?

The easiest way is to use an oil pressure switch. The switch will stop the pump whenever the oil pressure in the engine goes away. So, whenever the engine is off, the pump will turn off automatically.

Some switches just do that. But how do I get the pump to run when I'm trying to start the motor and the oil pressure's not up yet?

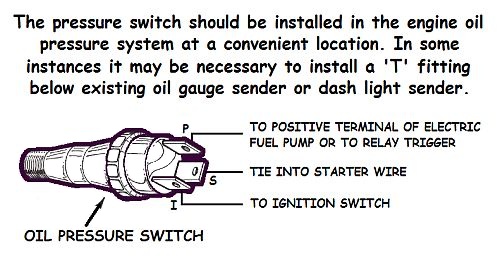

You use a three prong switch like this Standard Ignition PS-64:

The switch will also let the pump run when you hit the starter because the engine doesn't have oil pressure yet.

One wire goes to the pump, one to the start circuit, and the other to the ignition circuit. So, when there is no oil pressure, the switch connects START to PUMP, and as soon as you start cranking it runs the pump. When the oil pressure comes up, the switch connects IGN to PUMP, for normal running. When oil pressure goes away (because you just hit that rock and tore the pan off the engine, for example) it again connects START to PUMP, and disconnects IGN from PUMP, so the pump shuts off.

-How should you wire an electric fuel pump?

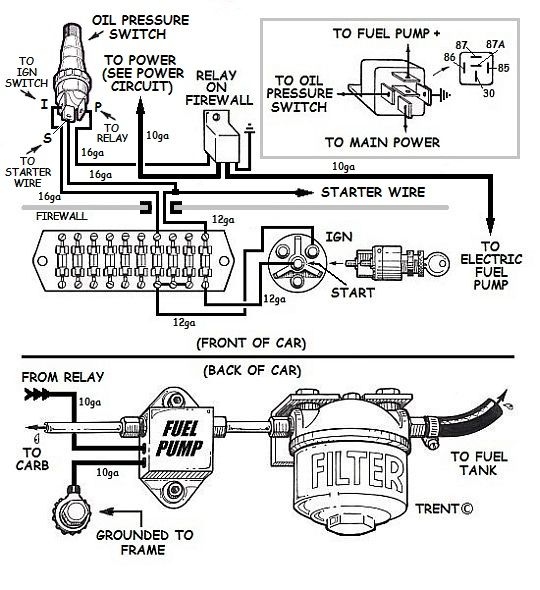

Since you need the fuel pump back by the tank and at the same level as the fuel or lower, that usually means you're going to have a long run of wire. So, you need to have really good wiring going back to it. Wiring that will carry enough current. Running the current through your ignition switch isn't a good idea since it's probably already overloaded, and will kill the voltage. That will kill the pump. However, it's nice for convenience. That's why a relay is really good to use.

It lets the ignition switch activate the pump, while keeping the power from having to run through it. It will keep your pump alive and happy because it is getting full voltage. A good way is to mount a relay beside a power distribution block on the firewall (see Improved Power Circuit) and get the power from there.

Here is a diagram on how to wire and plumb your pump:

Comments

Post a Comment